Laboratories

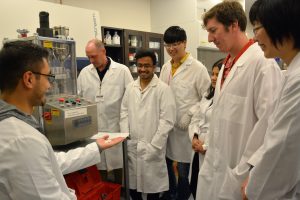

LAB 1 – Preformulation

Evaluate properties of a pharmaceutical API, powders and polymers utilizing:

- Particle surface area analysis

- Porosity analysis

- Particle size and shape analysis

- Density analysis

- Moisture adsorption/desorption isotherms

- Texture analysis

- Thermogravimetric analysis

- Differential scanning calorimetry

|

|

LAB 2 – Granulation and Extrusion/Spheronization

Processing of a pharmaceutical API and excipients to form granules and extrudates by:

- High shear mixing and wet granulation

- Low shear mixing and wet granulation

- Extrusion/Spheronization

- Fluid bed drying

|

|

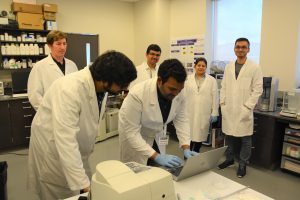

LAB 3 – Tableting

Evaluate excipient/drug compressibility and compressibility of wet granulated vs. direct compression tablet formulations utilizing:

- Instrumented single punch tablet press

- Instrumented rotary tablet press

- Equipment to monitor weight, thickness and breaking strength of tablet compacts

- Software to determine scalability from small to large scale production presses

|

|

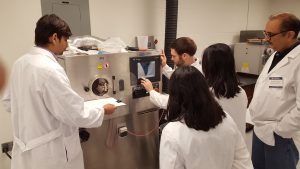

LAB 4 – Hot Melt Extrusion, 3D Printing and Tablet Evaluation

Evaluate processing of hot melt extruded forms using:

- Hot melt extruder

- 3D Printing

Perform tests to evaluate quality control attributes of tablets using:

- Tablet dissolution apparatus, real time and interval drug release testing

- Tablet disintegration testing

- Tablet friability testing

|

|

LAB 5 – Fluid Bed Granulation/Particle Coating and Tablet Pan Coating

Evaluate granulation of an API/excipient blend and film coating of non-pareil particles using:

- Fluid bed granulator/Wurster particle coater

Pan coat tablets using:

- Side vented tablet coating pan

|

|

Upcoming Courses

- May 19 – 24, 2024 Hands-on Course in Tablet Technology (Oxford, MS)